Process analysis of low capacitance lithium batteries

If planning experience or past batches have now admittedly told us that planning is not the cause of low capacitance, then the anomaly of process formation is highly suspect.

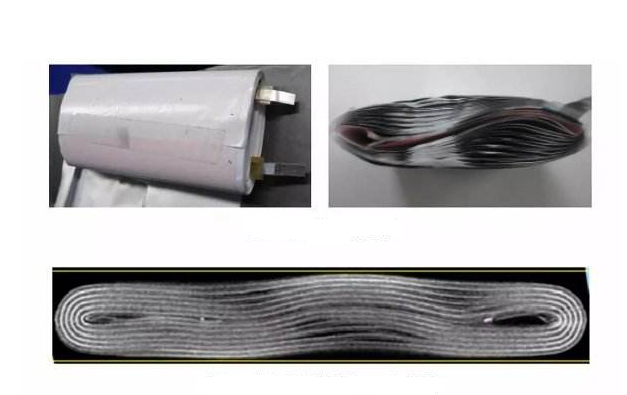

Low cell capacitance can be formed directly from a light positive or negative coating. When the positive electrode is lightly coated, the interface of a fully charged core will not have anomalies, at this time the need to acknowledge the problem by baking the method of measuring the positive electrode sheet components given by Wenwu in the “ideas”. The cathode as the lithium ion acceptor, the supply of embedded lithium orientation must be greater than the number of lithium source supply cathode, otherwise the remaining lithium will be precipitated in the cathode appearance, thus forming a thin layer of more uniform lithium precipitation. As mentioned above, because the negative electrode film component can not be taken directly from the baking component of the core disassembled electrode film, so one can make another test to find the weight gain ratio of the negative electrode to calculate the coating component through the baking component of the core disassembled negative electrode film, the second is to be able to compare the relative amount of low capacity and qualified cells or lithium-dialysis cell and lithium-dialysis cell negative electrode (full or non-charged does not matter, because the comparison is the relative component), if the qualified cell negative electrode, then the negative electrode will be the same as the qualified cell negative electrode. Relative weight to focus on some and together with the low capacitance core cathode showed a thin layer of cathode lithium precipitation, the cathode excess lack of possibility is very large. In addition, the anode or cathode coated cathode and anode will also form a low capacity, which is mainly negative single-sided coating light, because even if the anode coated heavy, although the g play will fall, but the total capacity will not fall but perhaps even increase. Discerning the cathode and anode surface is very simple, one side of the interface OK side of lithium analysis can be concluded as the cathode and anode surface, if the cathode process for the dislocation of the coating, directly compared to the relative weight ratio of baked single-sided, as long as the data similar to the A-side than the B-side coated 6% lighter data to determine the problem at all, of course, if the problem of low capacity is very serious, then the further inference of the actual surface density of the A / B-side is also there! necessary. (If the negative head and tail are aligned coated, then Fumu can’t find a good way to weigh the single-sided component at the moment, together with the hope that experienced friends to give advice) Roll pressure will damage the structure of the data, thus affecting the performance of the capacity. The reason why a data has functions such as capacity, voltage, etc., is because of its molecular or atomic structure. When the positive roller pressure density exceeds the process value (the reason may be that the thickness of the roller pressure is lower than the lower limit of the process, but more likely the elements are coated heavy and continue to roll pressure according to the original roller pressure process), the core of the positive electrode after dismantling the film will be very bright. If the anode compaction is too large, after winding the anode piece is easy to break piece will also form low capacity. However, because the positive dielectric will be formed once the positive piece is broken, the positive roller pressure itself requires a lot of pressure, so the frequency of encountering the positive dielectric will be much lower than the negative dielectric. When the cathode crush, the cathode appearance will form a strip or a piece of lithium precipitation (with an excessive lack of cathode simply cover the entire thin layer of lithium precipitation difference in the cathode appearance), together with the amount of liquid retention of the cell will be significantly reduced. When the compaction is further added, the lithium block added, the amount of lithium precipitation (lithium precipitation color whitish degree) will also be added, the core exterior platinum two colors clear and very dry, looks even sickening.

Water content overspend will also form low capacity. When the core injection before the water electrode water content overspending, liquid injection glove box dew point failed, the electrolyte water content overspending, in addition to the introduction of water gas two seals, the core may have low capacity. However, when the water content exceeds a certain value (the water content in the electrolyte sheet before injection is more than 250ppm, which is for reference only), the remaining water will damage the SEI film and consume the lithium salt in the electrolyte, thus reducing the capacity of the cell. The water content of the overspent cell full negative electrode is a small piece of dark brown.

When analyzing the low capacity, if you know what you are doing now, you can randomly remove a few bad appearance of the cells can be fundamental recognition of the problem, if the low capacity of the formation of a batch of lost needs detailed report, or the reason for the low capacity is not seen before, the need to be down to earth from the collection of process data, compared to low capacity and qualified cells, improvement plan for detailed analysis; especially the new recognition of a low capacity they have not seen! Before the situation, there must be repeated serious tests or at least process anomaly data collection as the basis for the conclusions drawn. The first few detailed analyses of the problem can help us develop a mindset to analyze the problem, and then when we encounter the problem again, we will be able to do so freely.

Post time: Aug-11-2020