Summary

As modern medical equipment is becoming more and more complex and miniaturized, more portable and more widely used in the home, many designers and manufacturers are looking for a smaller and portable energy source, while at the same time wanting the largest Power and performance.

Lithium batteries are small in size, light in weight, and have a long service life due to their high energy density. This makes them ideal for medical equipment and medical electrical equipment. Lithium and lithium ion batteries are used to power many medical devices and medical electrical equipment: including automatic external defibrillators, surgical power tools, robotic cameras, RFID asset tags, infusion pumps, bone growth stimulators, blood glucose monitors, blood Oxygen meter and cautery, hearing aids, cardiac pacemakers, surgical tools, medical defibrillators, robots, infusion pumps, monitors and meters, etc. Lithium battery chemicals can provide the highest specific energy (energy per unit weight) and energy density (energy per unit volume) of any type of battery, and the nominal open circuit voltage range is 1.7V to 3.9V, thereby making the product compact.

Due to its high energy density, lithium batteries are prone to overheating and may cause fire, so they have been classified as dangerous goods. In order to be transported, they must meet certain regulations specified in the global UN 38.3 standard. The standard applies to all areas in the lithium battery transportation chain: sub-suppliers of final product manufacturers; manufacturers to distributors; in-product or out-of-product; in this area; during product returns; or in non-original packaging. As the use of these batteries becomes more and more common, it is important for the medical industry to become familiar with these requirements.

UN 38.3 applies to batteries transported by themselves or in equipment. It is a universal standard that has been adopted by regulators and authorities worldwide, which is a requirement to enter multiple and even global markets. The UN 38.3 agreement is a key component of hazardous regulations, including identification / classification of lithium batteries, testing / qualification requirements, design guidelines / conditions, and packaging / transport obligations.

How to make batteries in medical devices more reliable?

The battery is a key component in medical equipment. As more and more instruments are computerized and become mobile, the performance and reliability of the system depends largely on the battery. Improvements in battery reliability are necessary. At present, there are three main problems in medical equipment batteries:

1. Insufficient quality assurance of medical batteries

2. Lack of knowledge of integrating batteries into medical devices

3. Don’t know when to replace the battery

The battery has human-like characteristics, and its health status depends on genetic composition, environmental conditions, and user patterns. The manufacturer specifies the operating time of a device with a battery performance of 100% (only for a short time). Most batteries in use are low. Over time, performance decreases and the battery’s energy storage becomes smaller. Most batteries can provide 300 to 500 discharge / charge cycles. There are fewer cases of complete discharge in harsh environments.

Most batteries can work normally in the first year, but confidence began to decline in the second and third years. New packaging was added, and over time, the battery pack became a mixture of good and bad batteries. That was when the headache started. Unless the battery is regularly checked as part of the quality assurance, the user knows almost nothing about the performance of each battery pack.

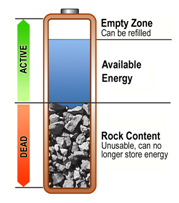

The energy in the battery can be divided into three parts: available energy, empty areas that can be refilled, and unusable parts or rock content that have become dormant and growing. Figure 1 illustrates these three parts graphically.

Figure 1: The three parts of the battery

The battery maintains its best performance for a limited time.

Equipment manufacturers must ensure that less than 100%

batteries are used for reliable operation.

The “Ready” indicator on the charger cannot verify the health of the battery; it only means that the battery is fully charged. As the battery space decreases, the charging time will also decrease. This can be compared to watering a jug filled with rocks. The short charging time keeps the battery low and puts it in a ready state; for those unsuspecting users who are full of confidence in the green light, they become a hidden disguise.

Now let us solve these problems and study possible remedies.

1. Insufficient quality assurance of medical batteries

To meet strict approval procedures, manufacturers select the best batteries from the battery pool. This satisfies the current needs, but ignores the tolerance of battery performance and the loss of capacity over time. As part of the regular quality inspection, the manufacturer may only check the voltage and internal resistance of the battery or battery; otherwise, the internal resistance of the battery or battery may be checked. Ability, leading health indicators are omitted, and for good reason. Capacity evaluation is complicated, and measurement by discharge / charge cycle prohibits time.

Electrochemical impedance spectroscopy (EIS) provides a promising solution in estimating capacity and detecting anomalies. This is of particular interest to battery manufacturers, so it is necessary to work closely to check which battery failures the EIS can identify. A matrix will need to be developed for each battery type to check each battery or battery against the “gold sample”. Tests of 15 to 30 seconds make this possible.

The US Food and Drug Administration (FDA) is a good solution to battery failures, noting that the estimated operating time provided by some implanted batteries is less than half, which implies a manufacturing deficiency. Insufficient battery power may cause patient fatigue. Doctors are trained to diagnose medical symptoms and are not familiar with the effects of battery fading. There are also cases where the implanted battery short-circuits and burns the patient’s tissue. As we rely more and more on batteries to maintain health, using advanced technology for quality control will ultimately reduce risk and lower medical costs.

2. Lack of knowledge of integrating batteries into medical devices

Regulators worry that equipment manufacturers do not pay enough attention to battery aging. There is no unified consumption model in terms of assessment capabilities; some medical devices are frequently used, while others are on standby, which makes the aging estimates somewhat different. Environmental conditions add further complexity. Safety during battery life is another issue that requires attention.

The battery performs best at room temperature, and the longest life expectancy under moderate pressure. “Smart” batteries benefit from displaying the remaining charge, but the fuel gauge reading may be turned off. In order to maintain accuracy, smart batteries need to be regularly calibrated to correct tracking errors between chemical batteries and digital batteries. Calibration should be performed every three months or after 40 partial cycles. If the device applies a periodic deep discharge by itself, no other calibration is required.

Even if it is sealed, some batteries still have vent holes to release the gas generated during use or exposure to pressure. Take the electric toothbrush as an example, in which exhaust is ignored. The engineer specified a waterproof device, but did not know that alkaline batteries will generate some gas during the discharge process. The gas accumulated in the toothbrush can cause an explosion and harm the user.

The modification of the Boeing B787 Dreamliner battery is another example that ignores battery behavior. Engineers estimate that the smoke incident on lithium-ion batteries only occurred once every 10 million hours of flight, but the two planes failed in less than 100,000 hours of flight. Mandatory battery modifications include: isolation of a single battery to prevent a chain reaction that occurs when overheating occurs; placing the battery in a steel container that can withstand fire without damaging the surrounding area; and the addition of a one-way vent to burn The gas in the battery is released to the outside. Designers of medical equipment can learn from this experience.

3. Don’t know when to replace the battery

A battery is a consumable component that gradually loses performance over time. Unlike car tires that can check for wear and replace tires when the tread is low, the battery is a black box that does not change color, size or weight. It exits according to its own schedule. The device manufacturer must make users aware of the symptoms of low battery power and prompt the battery replacement policy. This is not well understood in the medical industry and needs attention. When the author of this article asked the user: “What capacity do you replace the battery with,” most people shrugged and said, “I don’t know.”

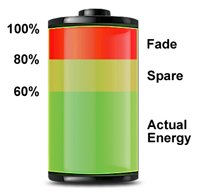

In addition to ensuring sufficient energy reserves, users of medical devices must also plan for the worst. Although the manufacturer did provide a certain amount of reserves, it was clearly not clearly defined at the FDA meeting. The energy reserves that are part of battery aging and worst-case scenarios vary by application. Mission-critical tasks require stricter requirements, and such batteries may need to be replaced sooner than less demanding uses that can tolerate unexpected failures. Figure 2 provides tolerances for fading and spares, bringing the available battery capacity to 60% in the worst case.

Figure 2: Calculating backup battery capacity

For the worst case, the spare capacity must be calculated.

The allowed capacity range is 80-100%; it is recommended

to use 20% of the spare capacity for critical purposes.

Some public safety organizations use batteries with the highest performance in critical applications, and pass battery packs with gradually decreasing capacity to roles with lower requirements. If a failure occurs, they can be replaced immediately. Placing the battery in different levels allows the battery to be used economically without sacrificing reliability. Only through battery maintenance can the capacity-based performance evaluation be reliably completed.

Understanding lithium thionyl chloride chemistry

Spool-type lithium thionyl chloride (LiSOCl 2) batteries are ideal for medical applications that require a low average daily current and a battery life of up to 40 years. The spool-type LiSOCl 2 battery can provide higher energy density and higher capacity, as well as a very low annual self-discharge rate. Typical applications include bone therapy equipment, oxygen meters and blood glucose meters.

Due to the lack of water and the chemical and physical stability of the electrolyte material, some spool-type LiSOCl 2 batteries can withstand high temperatures of up to 125 ° C, enabling the device to be autoclaved or chemically sterilized without removing the battery.

A typical example is Awarepoint’s battery-powered radio frequency identification (RFID) real-time location system (RTLS), which continuously monitors the location and status of medical devices. Environmental testing conducted by Awarepoint shows that the spool-type LiSOCl 2 battery can withstand temperatures of + 135 ° C and can work continuously for 500 steam sterilization cycles. The battery is compact, lightweight and powerful. It can provide a capacity of 0.55Ah at a current of 0.5mA. It also has complete safety. It is UL recognized and considered non-hazardous when shipped from the factory.

The spool-type LiSOCl 2 cells can also be modified to operate at a temperature of -80 ° C for use in the medical cold chain, enabling continuous monitoring of frozen tissue samples, transplanted organs, medical supplies, and pharmaceuticals during transportation.

However, please note that the creation of LiSOCl 2 batteries is not the same. The average annual self-discharge rate of high-quality batteries can reach 0.7%, while the annual self-discharge rate of inferior LiSOCl 2 batteries can be as high as 3% per year. For automatic external defibrillators (AEDs) that can remain idle for many years but need to operate reliably in an emergency, it makes sense to choose the best quality spool-type LiSOCl 2 battery that has the lowest annual self-discharge performance possible.

Hybrid battery powers high-current pulse applications

The hybrid version of the spool-type LiSOCl 2 battery combines a standard battery with a patented hybrid layer capacitor (HLC), which, like a rechargeable battery, provides the periodic high pulses required by an external defibrillator.

Using similar technology to manufacture lithium metal oxide batteries, even at extreme temperatures, can provide high voltage and high energy density, and has instant activation and extended life. Lithium metal oxide batteries can provide an open circuit voltage of 4.0 V for a limited time, a high pulse of up to 15A and a continuous current of 5A at 3.2V. These powerful small batteries are commonly used in handheld surgical power tools and cautery, making handheld devices lighter and more compact.

For example, the BioAccess portable small bone drill is powered by an alkaline battery pack, which has good performance and excellent reliability. By replacing 6 AA-type TLM-1550HP lithium metal oxide batteries with alkaline batteries, BioAccess reduced its weight by 36% and its volume by only 40%. An equivalent alkaline battery pack will require 3 times the weight and 2.5 times the volume (15 AA size alkaline batteries versus 6 AA size TLM-1550-HP batteries). The use of lithium metal oxide battery packs also enables surgical drills to have faster drilling speeds, longer effective drilling times (up to 30 to 40 seconds, up to 20 to 30 cycles at a time), greater instantaneous power and The greater the stall torque, therefore reducing operator fatigue during a more effective drilling cycle.

Industrial grade rechargeable lithium ion battery

Currently, many medical devices are powered by consumer-grade lithium-ion (Li-ion) rechargeable batteries. Consumer lithium-ion batteries have inherent shortcomings, including a short service life (up to 5 years and 500 charge cycles), a high annual self-discharge rate (up to 60% per year) and a limited temperature range (0 ° C to 60 ° C)), cannot be charged or discharged at extreme temperatures.

Industrial-grade rechargeable lithium-ion batteries are now available with a 20-year lifespan and 5,000 full charge cycles, capable of providing high current pulses (up to 5A) and a wider temperature range (-40 ° C to 85 ° C) C) Ability to discharge and charge at extreme temperatures (10 hour rate).

By combining telematics and GPS tracking equipment with heart rate, temperature and other advanced sensors (used to monitor the health and location of hospitals, nursing homes, assisted living areas or remote patients), industrial-grade lithium-ion batteries may see huge Growth opportunities. These and other emerging medical technologies will benefit from reliable long-term battery-powered solutions.

Post time: Apr-26-2020